- HOME

- ABOUT US

-

PRODUCTS

- Energy Meter

-

Power Transmission & Distribution

- Analog Meter

- Dehumidifier

- Wireless Temperature Meter and Sensor

- Fault Indicator

- High Voltage lndicator

- Electromagnetic Lock

- Relay

- Temperature and Humidity Control

- Fan

- Heater

- Lightning arrester

- Transformer

- Transmitter

- Fuse

- Breaker

- AC Contactor

- Intelligent Circuit Breaker

- Fire power detector

- Intelligent control

- Water Meter

- Fire Electric

- New Energy

- Home Terminal

- CONTACT US

- NEWS

- FAQ

Home

PRODUCTS

Power Transmission & Distribution

Dehumidifier

WA100E Vertical Plastic Case Intelligent Electrical Cabinet Dehumidifier

PRODUCTS

WA100E Vertical Plastic Case Intelligent Electrical Cabinet Dehumidifier

In order to ensure the safe operation of the power grid system and the long life, safe and effective use of the electrical equipment, the power system has put forward higher requirements for moisture-proof and condensation-proof cabinet.

Product Description

General

Intelligent dehumidification device is the use of semiconductor refrigeration dehumidification mode, the humid air in the confined space will be actively drawn into the dehumidification duct under the action of the fan, the water vapour in the air through the semiconductor refrigeration mechanism condenses into water, and then discharged from the cabinet through the conduit pipe, which can achieve good dehumidification effect. By reducing the water content in the air, the relative humidity and absolute temperature will be reduced at the same time, and the temperature will not be raised at all, so that the negative impact of temperature difference will not be produced, and the occurrence of accidents will be fundamentally eliminated or reduced, and the aging of the devices in the cabinet and the cabinet will not be accelerated due to the high temperature.

In order to ensure the safe operation of the power grid system and the long life, safe and effective use of the electrical equipment, the power system has put forward higher requirements for moisture-proof and condensation-proof cabinet.

●Advanced high-performance industrial-grade microprocessor, strong data processing and information storage capacity, high reliability and fast operation speed;

●Automatic operation and manual dehumidification function switching, dehumidification start value and humidity disconnection value adjustable;

●Dehumidification air duct active condensation, discharge gas heating and cooling, effectively achieving a comprehensive treatment of moisture and dehumidification of the closed space of the electrical cabinet.

●The system can effectively achieve the comprehensive treatment of moisture prevention and dehumidification in the confined space of electrical cabinet;

●Humidity and temperature sensors 24 hours real-time sampling, exceeding the set start value automatically lead to condensation; humidity and temperature settings have a memory function, will not be lost because of stopping the machine.

●The humidity and temperature settings have memory function, and will not be lost because of stopping and switching on the machine;

Fault display function, can quickly find the fault point to ensure normal operation;

The circuit board has moisture-proof treatment to ensure normal operation in humid environment;

●Online real-time temperature measurement, high precision and real-time measurement;

●Adopting advanced storage technology to achieve that the set parameters can still be saved after power down;

●Adopting rail mounting mode, simple wiring and very convenient disassembly and installation;

●The device is small in shape, occupies little space, and is equipped with standard opening dimensions for strong applicability;

●With communication function: adopting RS485 communication interface and MODBUS-RTU protocol, it can upload the measurement information and other parameters to the backstage monitoring and control system, and realise the remote control of online data.

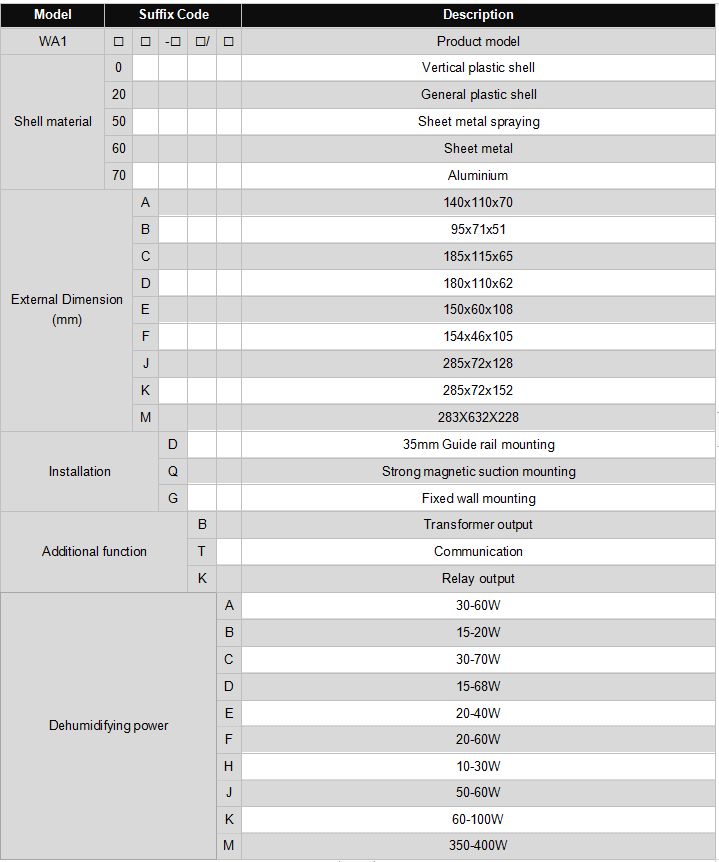

Model Description

Specification

|

Item |

Parameter |

|

Working power Supply |

AC/DC220V |

|

Power (Output) |

≤40W (Dehumidifying power 20-40W) |

|

Communication interface |

RS485 (isolated), MODBUS-RTU communication protocol, one start bit, 8 data bits, no parity, one stop bit |

|

Temperature measurement range |

1%RH~99%RH |

|

Humidity measurement accuracy |

±3%RH |

|

Temperature measurement range |

-20℃~+80℃ |

|

Temperature measurement accuracy |

±0.5℃ |

|

Recommended dehumidifying space |

≤3m³ |

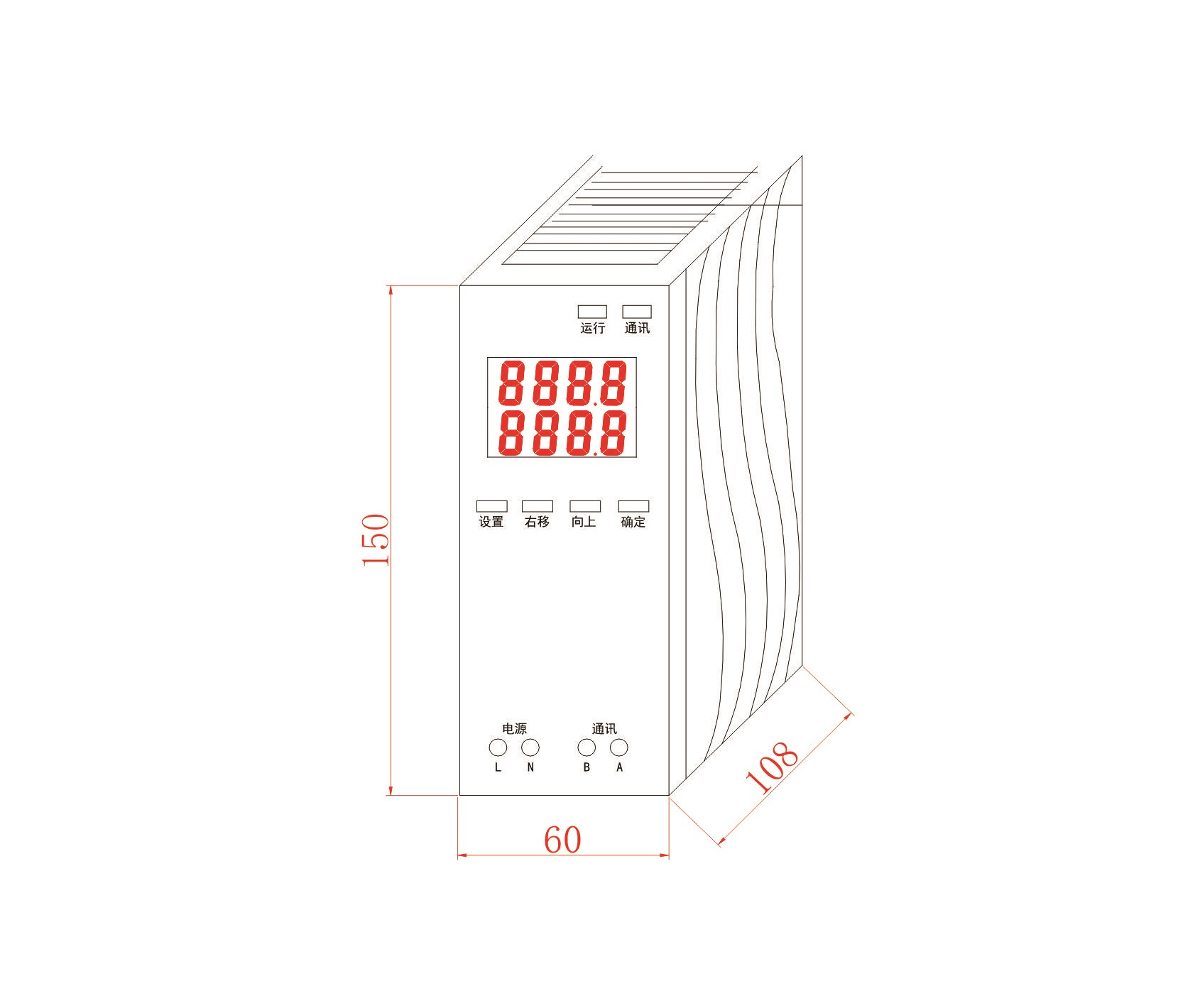

Dimension

English

English